Machine and Process Management, A Profit Engine for Industries

It might appear like an obvious explanation but innovation can majorly affect the benefit of a business. At the point when the correct advancements are applied to all right zones, they can have an enormous effect to proficiency and, at last, productivity . This is applied both for the technologies that maintain the business and for those that drive activities. Enter Smart Control, which is tied in with controlling all your basic business factors progressively. The innovation can transform your industrial automation frameworks and investments into an important and capable Profit Engine.

Try not to get left behind

Regardless of whether an organization can control the proficiency of their tasks and procedures well progressively, dealing with the business in a value-based way, i.e., as per simulated and human time plans, never works in todays fast moving condition. Attempting to oversee operational benefit month to month is illogical and unsustainable on the grounds that when you get refreshes from your enterprise resource planning framework, the data is never again significant to the business choices you have to make, or ought to have made. So you get yourself constantly under-performing, pursuing an ever elusive equilbrium.

Real real-time control

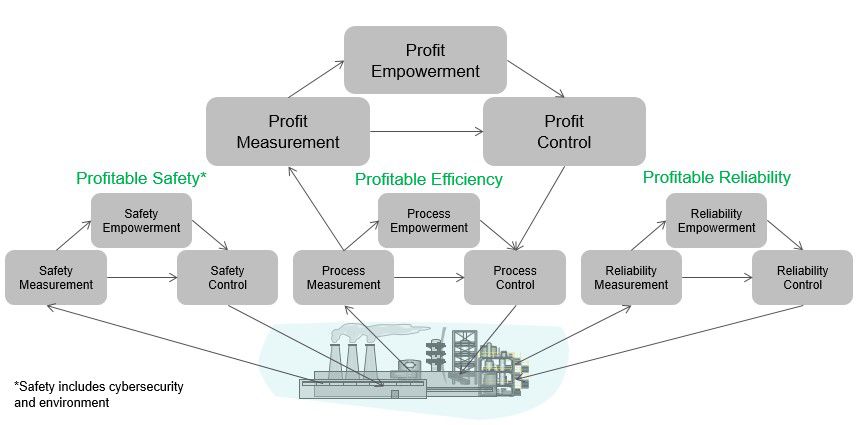

To break this cycle, you have to start controlling something other than the ongoing productivity of your tasks. You have to start to control other basic business factors continuously, as well, similar to your security (counting ecological wellbeing), unwavering quality, and, particularly, your operational productivity. In the event that you genuinely need to control your business execution progressively, all these business factors – which have customarily been overseen day by day, week after week, or month to month – should now additionally be controlled continuously.

In any case, there's no compelling reason to give up. The Industrial Internet of Things and all the availability it empowers, when connected effectively, can free organizations caught in an obsolete worldview and help them to acknowledge its exceptional benefit.

From more control to more benefits

Unlike conventional process control that focused only on enhancing the effectiveness of the task the present innovation can enable organizations to take it so significantly further. On account of greater availability and processing power, more quick witted, associated items, e.g., pumps, would now be able to control, screen, and secure themselves to wind up self-governing resources. This better, programmed ongoing control would then be able to be expanded upward, from hardware resources for unit resource sets to plant resource sets et cetera, as far as possible up to esteem chain resource sets.

In the era of the IIoT, business chiefs and plant work force, alike, have never had progressively or better chances to gauge and enhance the productivity of their activities in real time. Driving operational benefit begins with improving the execution of each mechanical resource so it does its activity in the most secure, most earth practical, dependable, and effective way conceivable.

Expanded network, processing force, and innovation implies it is conceivable to put real time control, interoperability, and correspondence at each level, from the least difficult plant resource as far as possible up to the supply chain. So presently, outfitted with the capacity to control each benefit continuously (even elusive resources like vitality, crude materials, and creation), organizations can direct business, particularly those capacities that have been generally value-based, not as indicated by any set calendar, but rather at whatever point it's most gainful for them.

That is the thing that Digital Control is about and how it drives plant productivity. It implies the venture can oversee and control all its business factors under a bound together technique. Operation and management are presently in sync: Management comprehends the ongoing variable imperatives of the activity, including wellbeing, unwavering quality, and security, and plant faculty comprehend the effects of these choices on operational productivity.

Stay updated :

Participate on our social stream.