Future of Industrial Automation

As manufacturing offices consolidates greater level of automation, the demand for new technology rapidly increases. The recent years reflect the way industry operates. With fast-paced automation development, it's an ideal opportunity to reflect on how automation trends will change the world in future.

Machine Learning: Enhancing Accuracy at Every Phase

Promising a response to numerous cutting edge producing challenges, machine learning is one area of innovation that has been liable to fast advancement in the most recent year. Machine learning depicts software engineering systems that enable a machine to freely take in an undertaking, as opposed to being modified to finish a task.

In the time of big data, the greatest interest of machine learning will come to manufacturers with information rich production lines. Utilizing the innovation, machines can get patterns and data from existing datasets.

Potential uses incorporate optical part arranging, mechanized quality control, disappointment recognition and enhanced profitability and proficiency. In fact, as indicated by National Institute of Standards, machine learning can enhance production limit by up to 20 percent and lower consumption of material by four percent.

Machine learning calculations can possibly convey more prominent precision to each period of production and it consist of numerous manufacturing frameworks that can - and do - utilize machine learning to enhance tasks.

Modularisation: Fulfilling the Need for Flexibility

Satisfying client request will always be a priority for manufacturers. Changing buyer needs and propensities expect makers to offer a more extensive scope of items, without decreasing item quality and consistency. Thinking about the aggressive idea of the present business, the possibility to make adaptable production lines couldn't be more important.

Modularisation enables manufacturers to discrete, associate or join distinctive production modules and create products in a single office. This change requires the interconnection of modern hardware and the usage of smart control programming.

Progressively, manufacturers are utilizing modularisation as a method to seed another market with a specific item, so as to demonstrate client request before a full-scale execution, in this way sparing time and assets.

Internet of Things: Industrial IoT

Internet of Things could not have existed without intelligent sensors, and the rising adoption of smart technology is changing the ways manufacturers implement IOT. The smart sensing technology is building stronger connectivity and analytics to supply chain. It is estimated that by 2020-2021, there will be up to 21 billion devices. IOT is emerging to be a huge scope as it provides businesses an opportunity to turn businesses into insights. It includes number of factors such as sophisticated sensors, device connections and evolution of lifestyle and mobility. The wireless availability is highly common in business organisations and development has spread into all the plants for manufacturing through WI-5 connected tablets and mobile devices. Its highly functional uses create significant development, expands profitability and enhances work efficiency in arenas of automation. The IOT application and services will help companies in refining their business process and create opportunities for better efficiency.

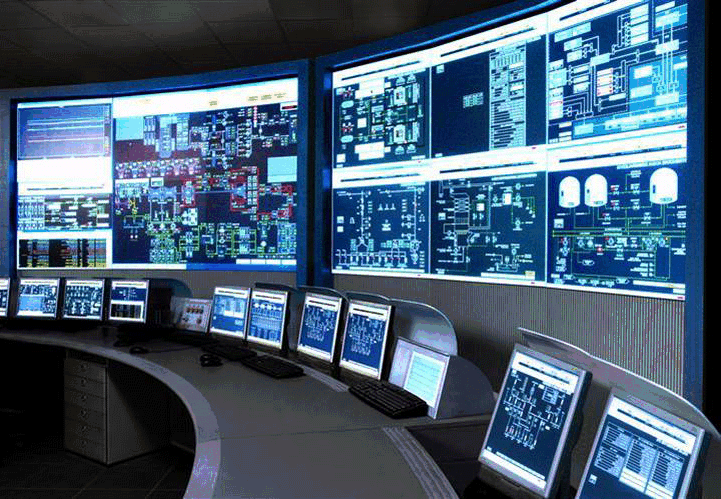

SCADA: More than Data Acquisition

SCADA applications holds an integral role in manufacturing. As per a report by worldwide statistical surveying firm Technavio, the assembling business is set to encounter a critical development in the selection of analytical software through SCADA.

The combination of predictive analytics in present day SCADA programming has made it simple for makers to gather and make future expectations in view of this insight. Therefore, SCADA frameworks give considerably more than an understanding into the life expectancy of machinery. The reconciliation of distributed computing with SCADA frameworks has empowered administrators to control production from any area, additionally enhancing the adaptability of the plant.

Similarly, as with the cloud relocation, there are security concerns. Nonetheless, as cloud security highlights turn out to be more modern and SCADA suppliers progressively receive a security by configuration way to deal with their product, this worry is probably not going to stop makers from grasping – and profiting from – cloud-based SCADA.

Digitalization is altering the world- and the production methods are ensuring long-term competitiveness. In order to respond appropriately, the plant operators have shortened their market time and become more flexible. The automation data is fed back to ensure continuous optimization of production.

Stay updated :

Participate on our social stream.